Ausgewählte Blogs

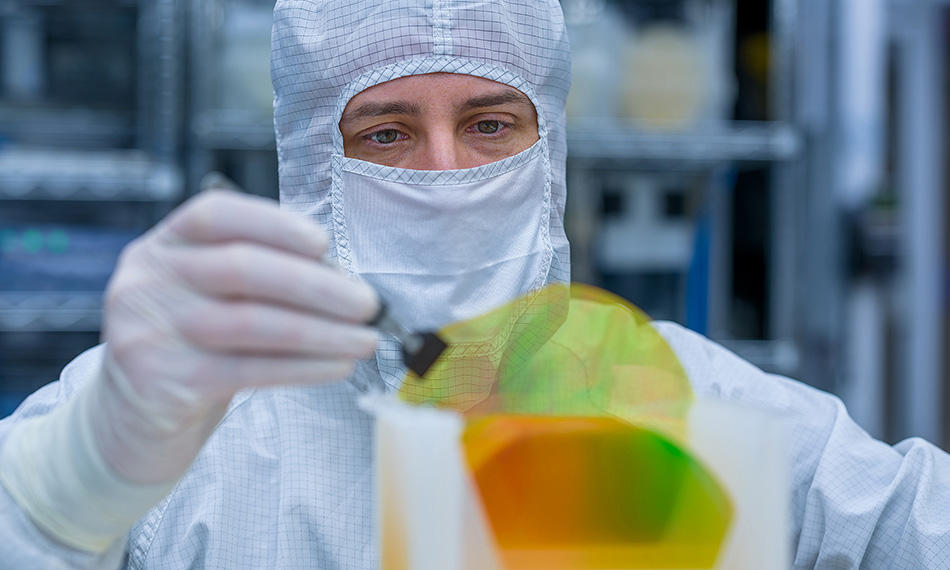

ANTRIEB VON ELEKTROFAHRZEUGEN

Entdecken Sie, warum Siliziumkarbid (SiC) perfekt für die Leistungselektronik von Elektrofahrzeugen ist.

KENNZEICHNUNG MEDIZINISCHER IMPLANTATE VERBESSERN

Erfahren Sie, wie die Coherent AP530 S einen USP-Laser mit Software und Robotik kombiniert.

LIEFERUNG VON OPTISCHEN SPEZIALFASERN

Erfahren Sie, warum unsere hochwertigen dotierten Fasern bessere Ergebnisse liefern - von der Chirurgie bis zur Raumfahrt.

VEREINFACHUNG VON MULTI-WELLENLÄNGEN-ANWENDUNGEN

Reduzieren Sie die Justagezeit von Tagen auf Minuten mit unseren vorjustierten Laser-Engines.

Vorgestellte Lösungen

Ausgewähltes Event

Die Battery Show Europe

18.-20. June 2024

Stuttgart, Germany, Booth D40

Die Battery Show Europe ist der führende Treffpunkt für die Gemeinschaft der fortschrittlichen Batterie- und H/EV-Technologie. Besuchen Sie uns an Stand 8-D40 und erfahren Sie, wie die Lasertechnologie in der Batterieproduktion eingesetzt werden kann.

Vorgestelltes Produkt

Coherent Optiken

Leistung, Zuverlässigkeit und Liefertreue

Entdecken Sie Polarisatoren, Filter, Kristalle, optische Fenster und vieles mehr. Durchsuchen Sie mehr als 100 optische Komponenten, Baugruppen und komplette Systeme.

Karriere bei Coherent

Unser multidisziplinäres Team von Wissenschaftlern und Ingenieuren kreiert radikal neue Ideen für das, was möglich ist, indem es maßgeschneiderte Lösungen für unsere Kunden entwickelt.

Coherent Labs

Wir lösen die schwierigsten Herausforderungen in der Fertigung mit Vordenkerqualitäten und innovativen Lasersystemlösungen. Unsere Experten arbeiten mit Kunden an über 2.500 Projekten pro Jahr.